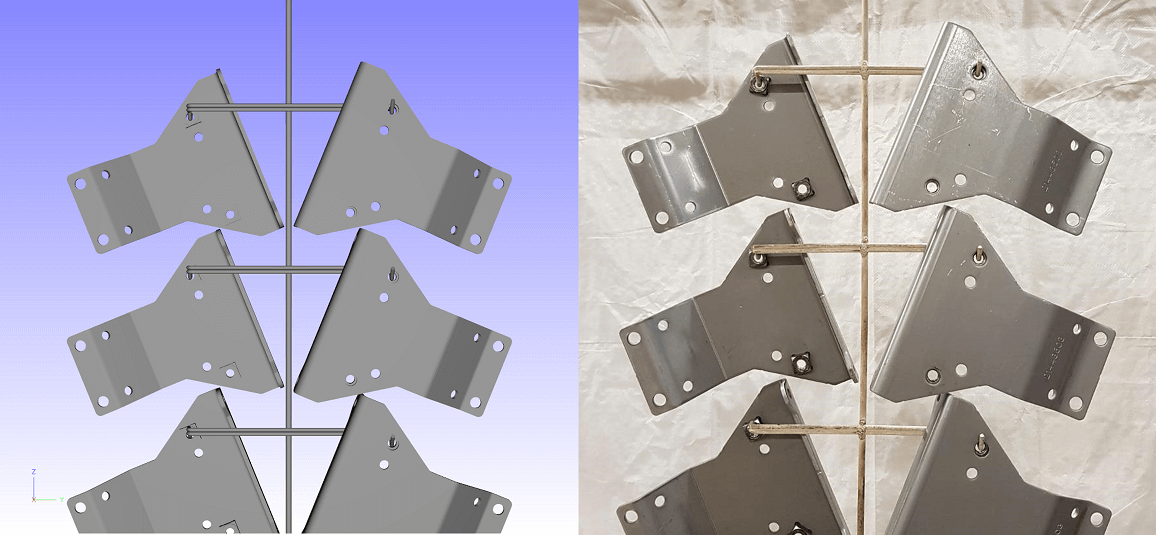

IPS Hanging Optimization

Easily create and optimize hanging patterns for conveyor systems to increase your throughput of parts.

IPS Hanging Optimization enables the user to find the optimal hanging pattern given a set of hanging fixtures and parts. The hanging patterns can be simulated along a conveyor to find an optimal spacing between hangers that avoids collisions and ensures a minimum clearance. The optimized hanging pattern design can directly be used with the IPS Spray module for paint thickness simulations.

Increase the efficiency of your painting line

Make cost estimates for new parts and hangers quick and precise

Input for automation and offline programming of robots

Evaluate and improve coating results

Center of mass calculations ensures accurate hanging positions